Introduction

Petroleum compounds are composed of hydrocarbon molecules of varying sizes and shapes. Molecular weight determines how a chemical reacts during separation. For example, ethane has two carbon atoms and butane has four. During separation, butane remains in the lower section and ethane moves up the tower. The smallest or lightest components in a tower have the lowest boiling points. A distillation column is built on the principle that light and heavy molecules have different boiling points.

Industry relies heavily upon this process to produce many of the chemicals we use today. For example, crude oil is a mixture of many of the chemicals used in modern manufacturing, including straight-run gasoline, naphtha, gas oil, various gases, salt, water, and clay. By knowing the temperature at which a chemical vaporizes, an operator can identify these specific components after they are heated, vaporized, and condensed on the different trays in a distillation column.

Distillation is a process that separates a substance from a mixture by its boiling point. This simple definition, however, does not explain the complex equipment arrangements that make up a distillation system. The distillation process includes a feed system, a preheat system, the distillation column, the overhead system, and the bottom system. The term system is frequently used to describe the various equipment arrangements associated with distillation.

The feed system is designed to safely store, blend, and transport the raw feedstock. This simple system is composed of tanks, pipes, valves, instrumentation, and pumps.

Preheating systems are designed to raise the temperature of the raw feedstock before it enters the distillation column. Various heat transfer devices are available for the process. Typically, a heat exchanger or a furnace system is used. Feed rates into and out of this system are carefully controlled.

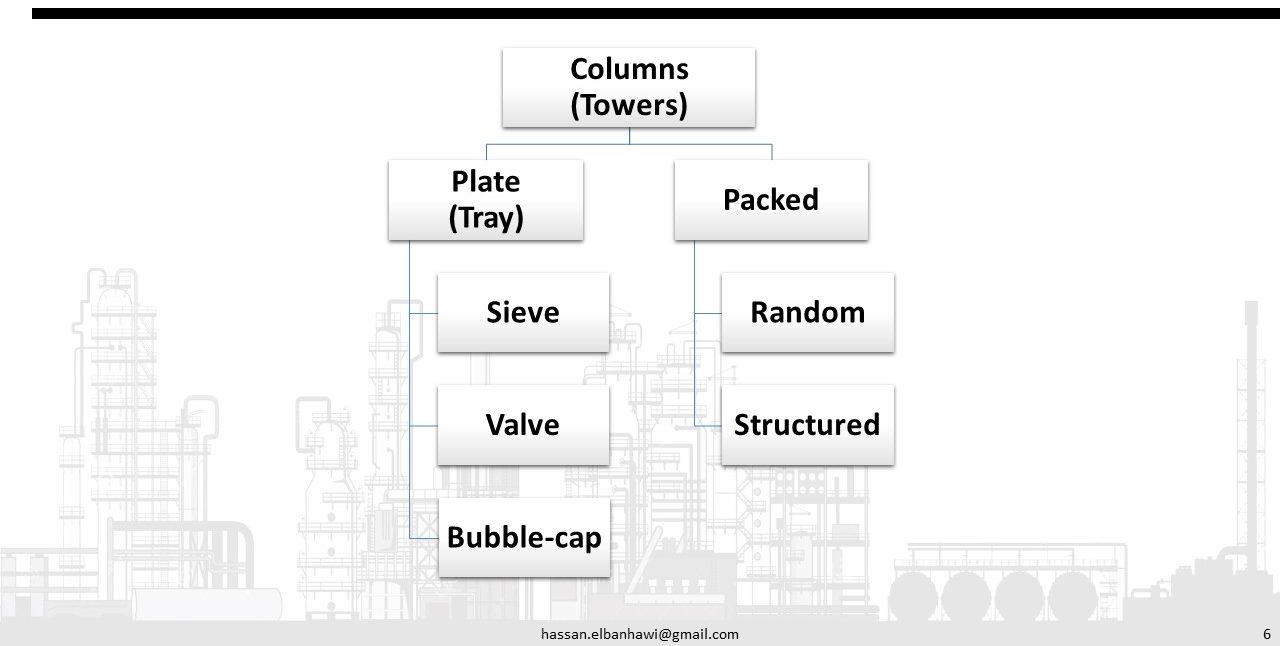

The distillation column can be a packed- or plate-type column. Plate columns have a series of trays stacked on top of each other. Packed columns are filled with packing material to enhance vapor-liquid contact. The function of each of these column types is to allow lighter components of the mixture to rise up the column while its heavier components drop down or, in other words, separate into various components by their boiling points. A variety of arrangements is available on the distillation column to condense the hot vapors and collect and separate the distillate.

The bottom system is composed of a section in the column designed to allow liquids to boil and roll freely. A reboiler is connected to this section to maintain and add heat energy into the liquid. The term reboil indicates that the liquid was originally boiling. Hot vapors are returned from the reboiler to the bottom of the column, below the bottom tray. A level control loop is used to keep the liquid at a predetermined level. In the bottom system, liquid level, temperature, and composition are carefully controlled.

A reboiler maintains the energy balance on the distillation column. Reboilers take suction off the bottom of the tower. The liquid in the tower is circulated through the reboiler. Vaporization occurs in the reboiler, and these vapors rise up through the tower. Boiling-up rate is defined as the balance of the products (vapor and liquid) returned to the column from the kettle reboiler.

The overhead system is used to cool off the hot overhead vapors. The condensed liquid is used as reflux or is transported to the tank farm as product. Reflux is returned to the top of the column to control product purity and tower temperature. In packed columns, a liquid feed distributor is used to evenly disperse the liquid. In a plate column, the reflux is pumped to the upper tray. Plate columns are not as sensitive to liquid feed distribution as packed columns are.

Classification

A distillation column is a tower with a series of trays or packing that provide contact points for the vapor and liquid. As vaporization occurs, the lighter components of the mixture move up the tower and are distributed on the various trays. The lightest component goes out the top of the tower in a vapor state and is passed over the cooling coils of a shell and tube condenser. As the hot vapor comes into contact with the coils, it condenses and is collected in the overhead accumulator. Part of this product is sent to storage while the rest is returned to the tower as reflux.

References

1-ENGINEERING DATA BOOK by Gas Processors Suppliers Association

2-Process Technology - Equipment and Systems by Charles E. Thomas